Post Harvest and Near Harvest Fruit Coatings

Post Harvest and Near Harvest Fruit Coatings

Post-harvest and near-harvest solutions are much needed for extending shelf life of fruits and vegetables (FNV), preserving quality and reducing losses throughout its journey from the farm to the table. Our biopolymer solution can be applied to the harvest to preserve freshness, reduce spoilage and extend shelf life without the use of synthetic chemicals and harmful residues.

Keep Fruits & Vegetables Fresh for longer - Naturally and Sustainably.

Keep Fruits & Vegetables Fresh for longer - Naturally and Sustainably.

Every extra day of shelf life added is Money saved.

Every 1% reduction in post-harvest loss can translate to ₹1,000 - 2,000 per tonne of additional revenue for the packer/exporter.

Extending shelf life by just 2 days can reduce stock rotation losses by 10–15%

Global fruit loss = >400 million tonnes per year (FAO, 2022)

The global economic loss exceeds USD 1 trillion annually across the FNV supply chain.

Integrate in your existing Packing Line

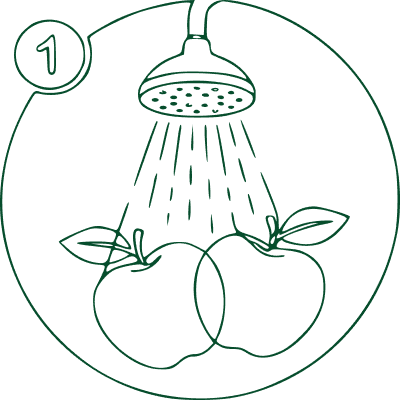

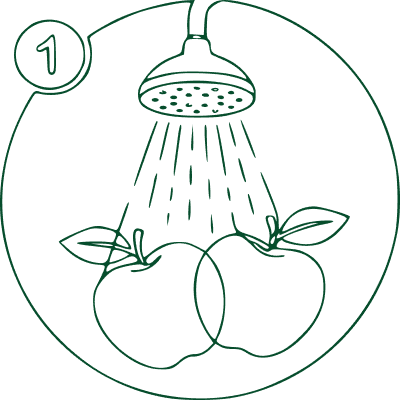

Wash and Sanitize fruits

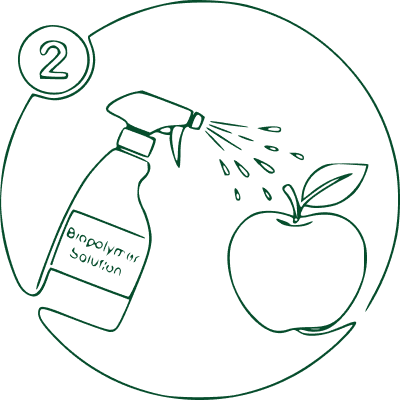

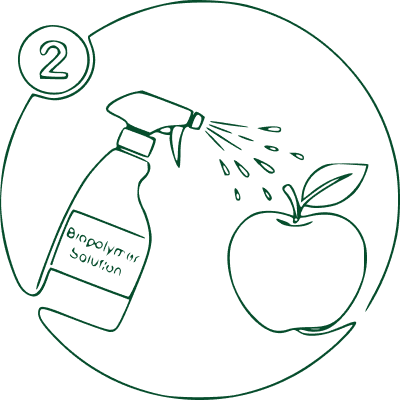

Dip or spray with biopolymer solution

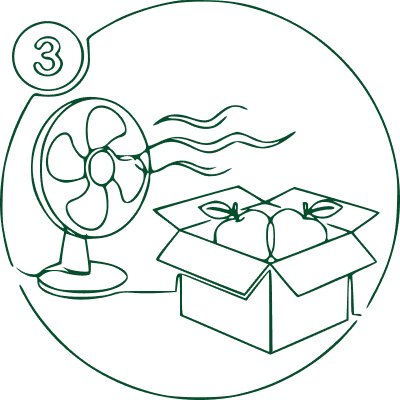

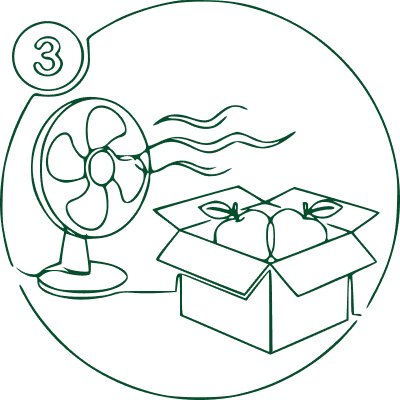

Dry and Pack

Spoilage of fresh produce leads to wastage and results in monetary losses for all key stakeholders in the supply chain. It can disrupt the supply chain, creating a shortage of supplies and leading to price rise. The industry is continuously looking for cost-effective and innovative solutions to extend the shelf life of fruits and vegetables (FNV) as they swiftly move from the farms to the markets and eventually on our tables. Most packing houses and exporters use synthetic wax or Shellac based coatings because they are easy to use and highly affordable.

On the otherhand, retailers are demanding natural and residue free solutions owing to increased consumer awareness and preferences. While new solutions are welcome, they must find easy adoption in the existing workflow. Our biopolymer solution comes in a liquid form and can be applied on the produce either by dipping the produce or spraying the solution on the produce. The above illustration explains the process in simple steps and is very much doable. The solution can be applied for a variety of fruits and vegetables – apples, mandarins, oranges, limes, pomegranate, bananas, avocado, mangoes and more – the list is endless. If you are looking to evaluate our solution on your produce, write to us on info@nizonamarineproducts.com and get in touch with our team of experts.

High spoilage due to delay in supply chain and last mile delivery.

Poor texture, color, moisture loss, shrivelling and nutrition loss.

High wastage due to rejections

Rising demand for cleaner solutions over synthetic chemicals

Fresh produce loss is systemic and massive

Can occur at near harvest stage due to improper harvesting and handling techniques or post harvest stage due to improper storage or transit conditions. A biopolymer coating can restrict spoilage and extend shelf life by 3 to 7 days. We help you address the following problems :

A natural and sustainable solution for farmers, packaging houses, exporters and grocery supply chains.

Keep Fruits & Vegetables Fresh for longer - Naturally and Sustainably.

Keep Fruits & Vegetables Fresh for longer - Naturally and Sustainably.

Post-harvest and near-harvest solutions are much needed for extending shelf life of fruits and vegetables (FNV), preserving quality and reducing losses throughout its journey from the farm to the table. Our biopolymer solution can be applied to the harvest to preserve freshness, reduce spoilage and extend shelf life without the use of synthetic chemicals and harmful residues.

Every extra day of shelf life added is Money saved.

Every 1% reduction in post-harvest loss can translate to ₹1,000 - 2,000 per tonne of additional revenue for the packer/exporter.

Global fruit loss = >400 million tonnes per year (FAO, 2022)

The global economic loss exceeds USD 1 trillion annually across the FNV supply chain.

Extending shelf life by just 2 days can reduce stock rotation losses by 10–15%

Fresh produce loss is systemic and massive

Can occur at near harvest stage due to improper harvesting and handling techniques or post harvest stage due to improper storage or transit conditions. A biopolymer coating can restrict spoilage and extend shelf life by 3 to 7 days. We help you address the following problems :

A natural and sustainable solution for farmers, packaging houses, exporters and grocery supply chains.

High spoilage due to delay in supply chain and last mile delivery.

Poor texture, color, moisture loss, shrivelling and nutrition loss.

High wastage due to rejections

Rising demand for cleaner solutions over synthetic chemicals

Integrate in your existing Packing Line

Wash and Sanitize fruits

Dip or spray with biopolymer solution

Dry and Pack

Spoilage of fresh produce leads to wastage and results in monetary losses for all key stakeholders in the supply chain. It can disrupt the supply chain, creating a shortage of supplies and leading to price rise. The industry is continuously looking for cost-effective and innovative solutions to extend the shelf life of fruits and vegetables (FNV) as they swiftly move from the farms to the markets and eventually on our tables. Most packing houses and exporters use synthetic wax or Shellac based coatings because they are easy to use and highly affordable.

On the otherhand, retailers are demanding natural and residue free solutions owing to increased consumer awareness and preferences. While new solutions are welcome, they must find easy adoption in the existing workflow. Our biopolymer solution comes in a liquid form and can be applied on the produce either by dipping the produce or spraying the solution on the produce. The above illustration explains the process in simple steps and is very much doable. The solution can be applied for a variety of fruits and vegetables – apples, mandarins, oranges, limes, pomegranate, bananas, avocado, mangoes and more – the list is endless. If you are looking to evaluate our solution on your produce, write to us on info@nizonamarineproducts.com and get in touch with our team of experts.

Need for Near & Post Harvest fruit treatment

Perishable nature of the produce

Fresh fruits and vegetables are highly perishable and can lose its palatability and marketability within 3 to 5 days if post harvest fruit treatment procedures are not carried out. Fresh produce such as fruits and vegetables (FNV) continue to respire and start losing moisture right after they are plucked. If the post harvest fruit treatment procedures are not performed, this continued biological activity leads to –Deterioration of color and textureWilting and shriveling due to loss of moisturePotential microbial infestations Spoilage resulting in rejections and wastageDisruption in supply chains

Retailers demand improved shelf life

Every extra day of freshness adds profits

Near Harvest Treatments to prevent losses before picking

Post Harvest Treatments to prevent losses after picking

Need for Near & Post Harvest fruit treatment

Perishable nature of the produce

Fresh fruits and vegetables are highly perishable and can lose its palatability and marketability within 3 to 5 days if post harvest fruit treatment procedures are not carried out. Fresh produce such as fruits and vegetables (FNV) continue to respire and start losing moisture right after they are plucked. If the post harvest fruit treatment procedures are not performed, this continued biological activity leads to –Deterioration of color and textureWilting and shriveling due to loss of moisturePotential microbial infestations Spoilage resulting in rejections and wastageDisruption in supply chains

Retailers demand improved shelf life

Every extra day of freshness adds profits

Near Harvest Treatments to prevent losses before picking

Post Harvest Treatments to prevent losses after picking

Whatever we produce,

We must fully use

Contact Us

Phone No:

022 4924 0706

+91 9730007882

Location:

923, IJMIMA complex, MDP Road, Malad West, Mumbai – 400064, Maharashtra, India.

71/17, Topsia Road, (South) Near Millat Nagar Masjid, Kolkata: 700046, West Bengal, India.

© 2026 Nizona Marine Products Private Limited. All Rights Reserved.

Whatever we produce,

We must fully use

Contact Us

Phone No:

022 4924 0706

+91 9730007882

Location:

923, IJMIMA complex, MDP Road, Malad West, Mumbai – 400064, Maharashtra, India.

71/17, Topsia Road, (South) Near Millat Nagar Masjid, Kolkata: 700046, West Bengal, India.

© 2026 Nizona Marine Products Private Limited. All Rights Reserved.

Whatever we produce,

We must fully use

Contact Us

Phone No:

022 4924 0706

+91 9730007882

Location:

923, IJMIMA complex, MDP Road, Malad West, Mumbai – 400064, Maharashtra, India.

71/17, Topsia Road, (South) Near Millat Nagar Masjid, Kolkata: 700046, West Bengal, India.

© 2026 Nizona Marine Products Private Limited. All Rights Reserved.