Ever heard of Stone paper or rock paper or Calcium carbonate paper? Well, this is a product resembling paper which is different from the conventional paper and does not make use of plant fibres for its preparation.

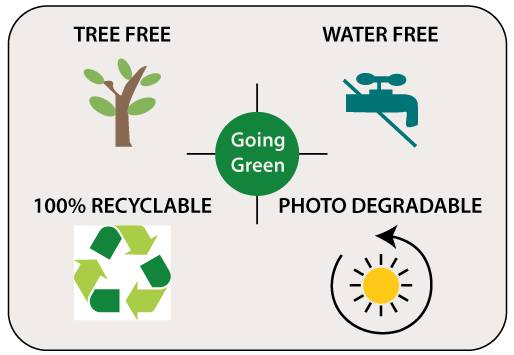

“Stone paper” also known as waste marble, mineral paper, or rich mineral paper. It is strong, durable and primarily made from calcium carbonate, one of the most common substances on the planet. Aside from making up part of marine organism shells, pearls, and eggshells, calcium carbonate is also a natural by-product of water and limestone that is found in quarries. Contrary to its name, Stone Paper is soft and subtle, with a clean, attractive, natural white colour. The Stone Paper that uses a mixture made for 80 percent of calcium carbonate and for 20 percent of a non-toxic resin (high-density polyethylene), is not only 100% recyclable but its manufacturing process is also eco-friendly. This paper, in fact, is manufactured without the need to fell trees, without polluting water and generating harmful gaseous wastes.

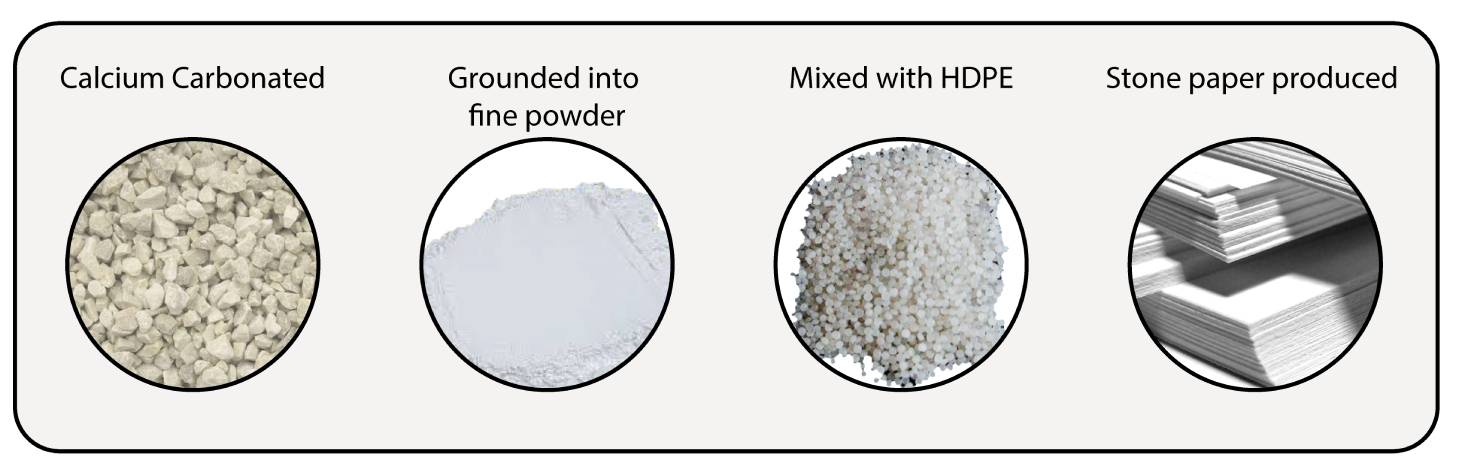

Calcium carbonate is no stranger to the paper world – for the past 30 years it has been used as a filter and a coating pigment to produce whiter, brighter, glossier paper. But in making stone paper, the mineral graduates from just being a simple coating to being the heart of the product, comprising 80 percent of its composition. The calcium carbonate is ground into a fine powder and mixed together with a small amount of high-density polyethylene (HDPE).

Rock paper is claimed to be very environmentally friendly paper. It is different from conventional paper because it does not use wood pulp as its raw material. The technology for making stone paper is also claimed not to pollute air and water; no chlorine or acid compounds used, and the resulting stone paper is really non-toxic and even food safe. It is also believed that the stone paper production process improves air, soil and water quality, and reduces energy consumption. The basic difference between stone paper and conventional paper is in terms of the raw materials used.

Conventional paper uses plant fibers as raw material and a lot of water in the production process, while stone paper does not use plant fibers and water at all in its production process. In addition, stone paper production produces low carbon emissions, no acid, base nor bleaching chemicals require, and stone paper can be recycled.

The process for creating the Stone Paper was developed and then patented by the Lung Meng Company in Taiwan in 1998. In addition to the environmental benefits, it has following features that make it a viable alternative to conventional paper.

- Anti-moth, anti-mildew, tear resistant, photodegradable

- Recyclable, soft, durable, oil resistant, water-proof, and stable in color. It is also claimed that stone paper can be written while it is wet.

- Flame-resistant, durable and waterproof.

- Lower ink absorption (30% less) during printing, allowing significant savings

- Lighter, reducing the weight of books or products to be transported.

Thank you for your reading. Join the conversation by posting a comment.